Device Set-up Mar. 2023 – Dec. 2024

⌜Designed, built, and maintained a custom low-noise experimental infrastructure for quantum device measurements within a dilution refrigerator. Led the customization of RF reflectometry lines, including the design of passive components like bias-tees using MATLAB. Performed comprehensive system validation using a Network Analyzer to characterize S-parameters and ensure signal integrity. Acquired extensive hands-on experience in cryostat maintenance, including 3He line cleaning and OVC disassembly.⌟

Probing the delicate quantum states of a semiconductor spin qubit requires an extremely well-isolated environment, necessitating millikelvin temperatures and meticulously engineered DC and RF lines to minimize noise-induced decoherence and ensure high-fidelity readout.

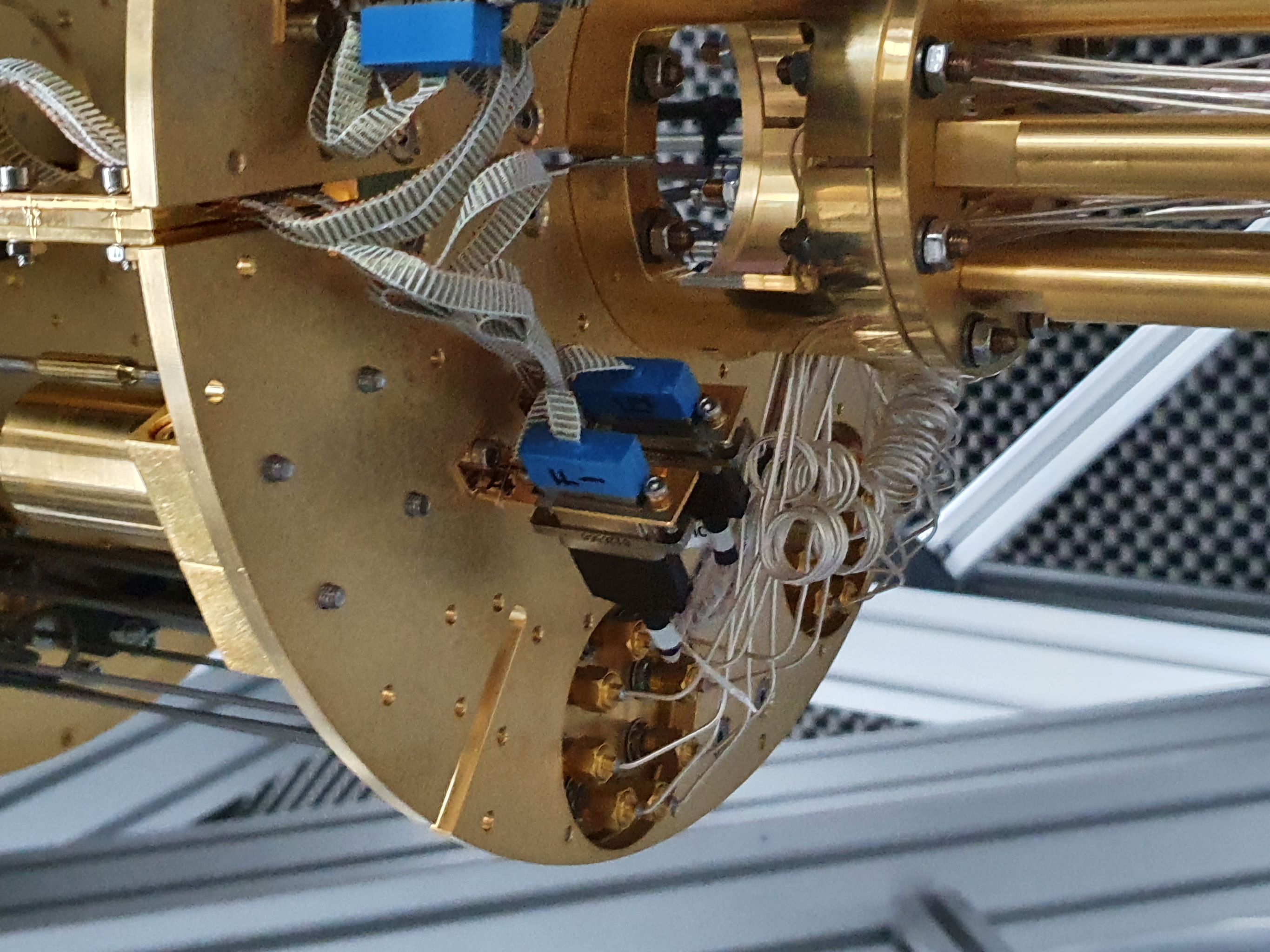

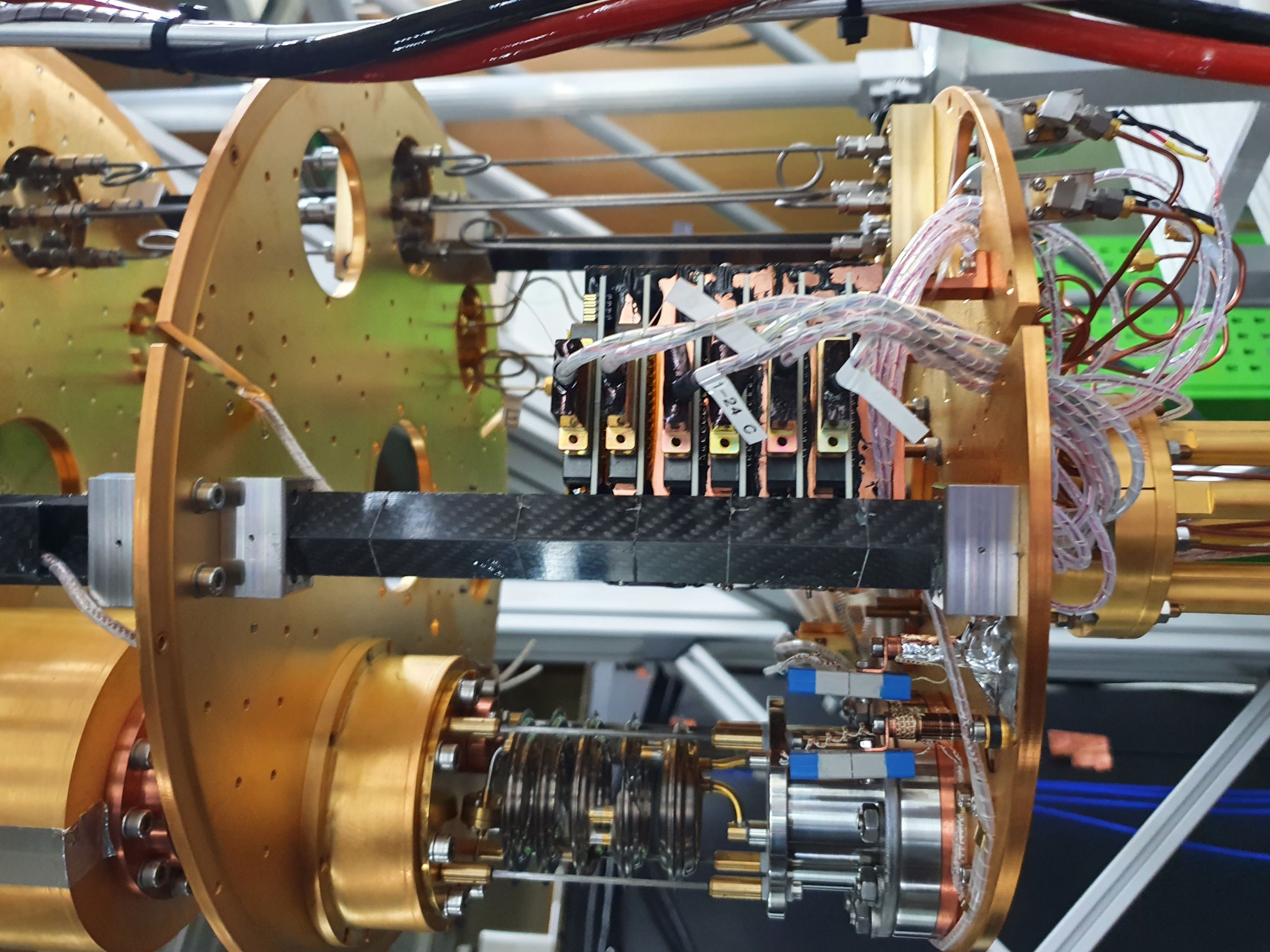

This project involved the comprehensive customization of a commercial Oxford Instruments Triton dilution refrigerator to meet the stringent demands of our experiments.

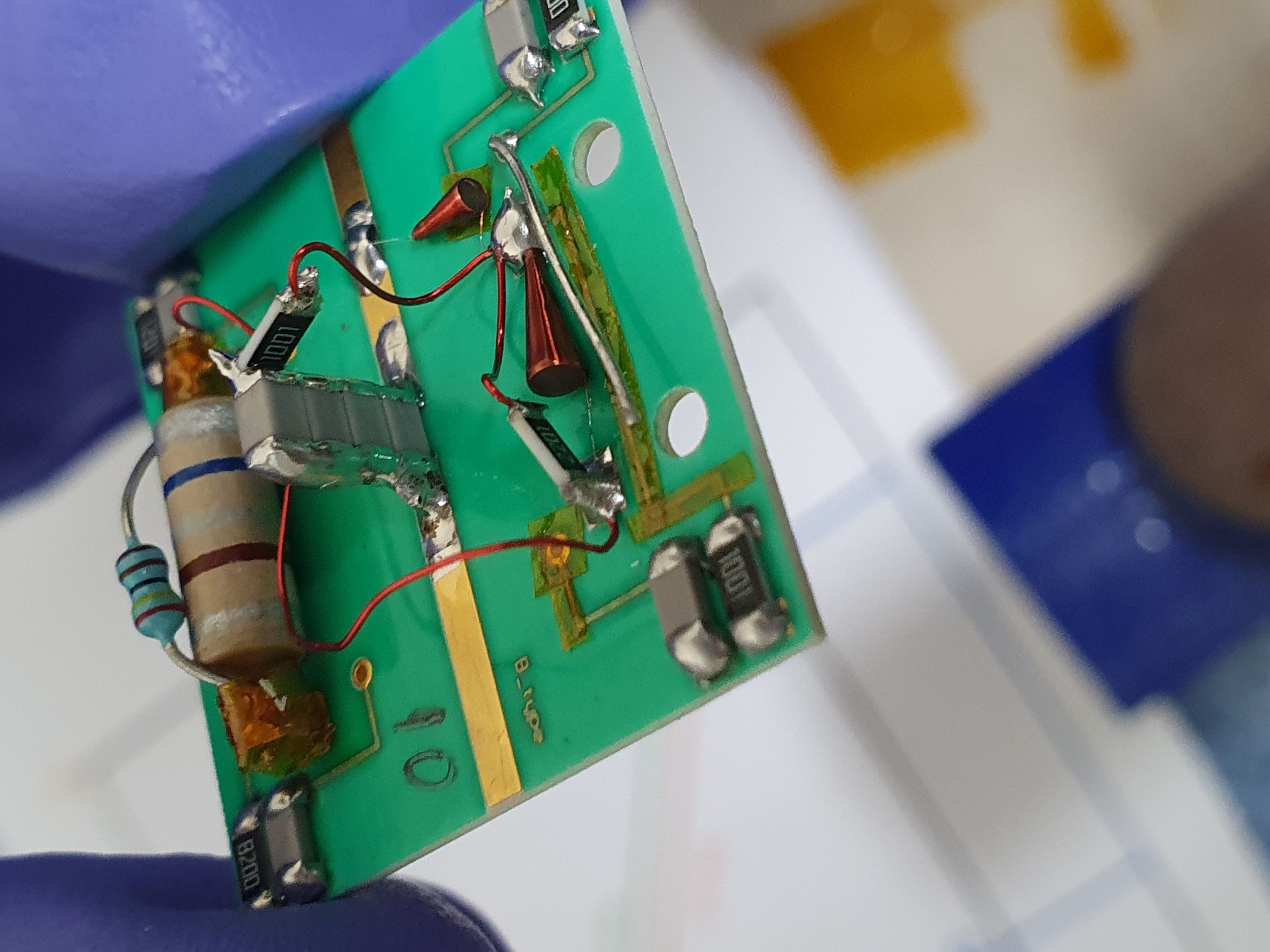

My contributions began at the most fundamental level, including preparing the equipment frame by scraping paint to ensure proper electrical grounding and shielding, and fabricating custom cables and performing high-quality soldering.

I also participated in the design of critical passive components, such as bias-tees, using MATLAB for simulation and layout.

A key part of my work was the end-to-end customization of the RF lines for fast qubit readout via RF reflectometry.

After installing components like attenuators and directional couplers, it was crucial to quantitatively verify their performance.

To do this, I utilized a Vector Network Analyzer (VNA) to characterize the frequency-dependent S-parameters of the fully assembled lines.

I measured S11 to confirm minimal signal reflection (impedance matching to 50 Ω) and S21/S12 to analyze signal transmission and distortion.

I then exported this data and used Python to analyze the waveform characteristics, ensuring that our control and readout pulses would arrive at the device with their integrity intact.

Beyond the initial setup and validation, I was also responsible for the regular maintenance and operation of the dilution refrigerator.

This provided me with deep, practical expertise in a range of essential procedures, including periodically replacing the liquid nitrogen trap, cleaning the ³He line to maintain cooling power, disassembling the outer vacuum chamber (OVC) for system modifications, and the entire cycle of sample loading and unloading.

This comprehensive experience has given me the skills to not only use but also troubleshoot and maintain the complex infrastructure required for cutting-edge quantum experiments.