Genetic-algorithm-based Micromagnet Shape Optimization Jan. 2025 – Jun. 2025

⌜Developed a custom genetic algorithm from scratch in Python to autonomously design complex micromagnet geometries. Implemented both mesh-based and advanced polygon-based representations, and integrated the algorithm with MuMax3 micromagnetic simulator to optimize on-chip magnetic field gradients for enhanced spin qubit coherence.⌟

The performance of spin qubits driven by Electric Dipole Spin Resonance (EDSR) is often limited by dephasing

caused by the same magnetic field gradients used to drive them.

While significant efforts in the field have focused on improving material properties or applying advanced denoising

protocols to enhance coherence,

the geometric optimization of the micromagnet itself has often been overlooked as a crucial degree of freedom.

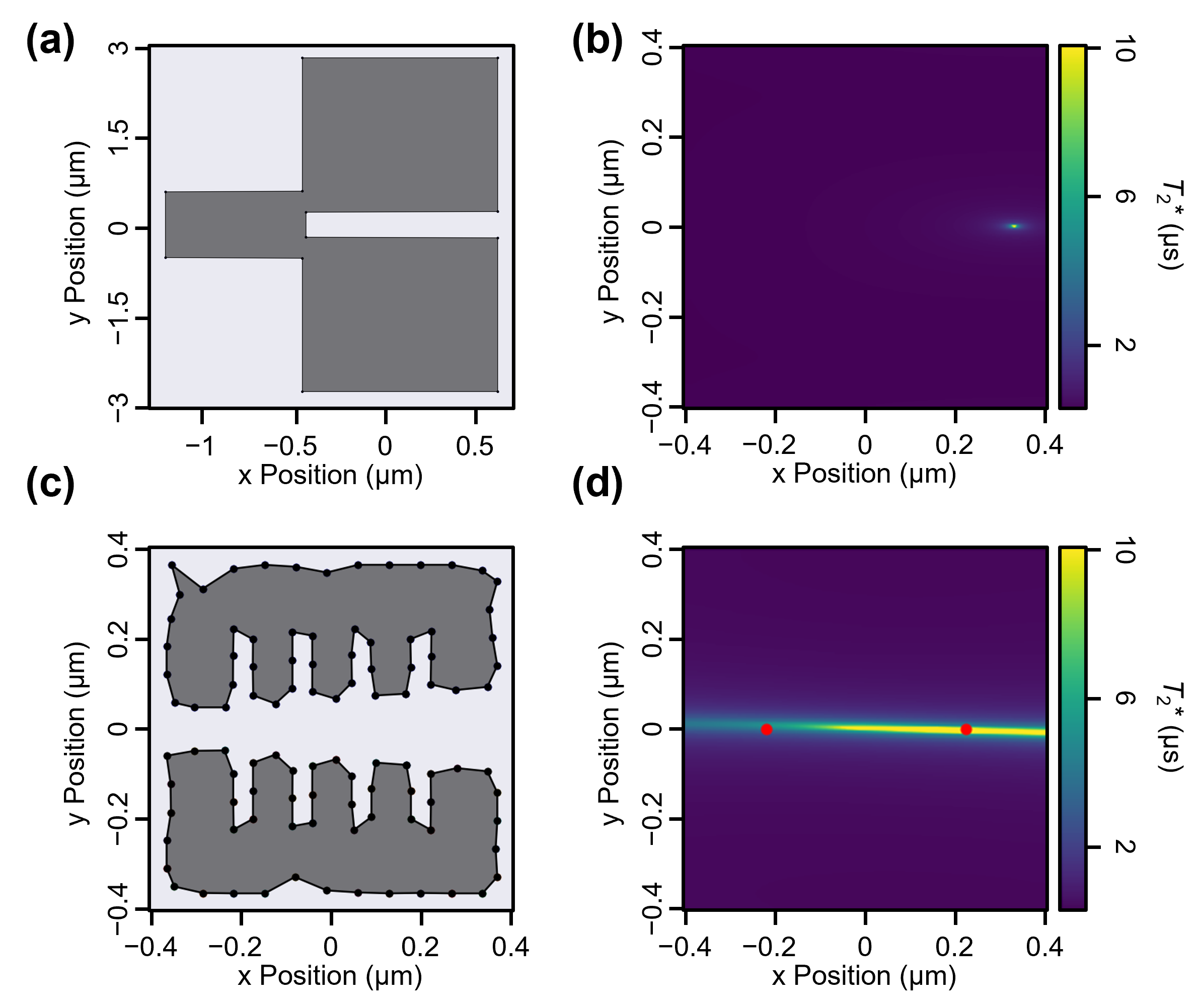

This project aimed to overcome this fundamental trade-off by

optimizing the physical shape of an on-chip micromagnet to create an extended "sweet spot"

of high qubit coherence (T2*). As the numerical nature of the problem precluded traditional gradient-based methods,

I developed a comprehensive, gradient-free Genetic Algorithm (GA) framework from scratch in Python

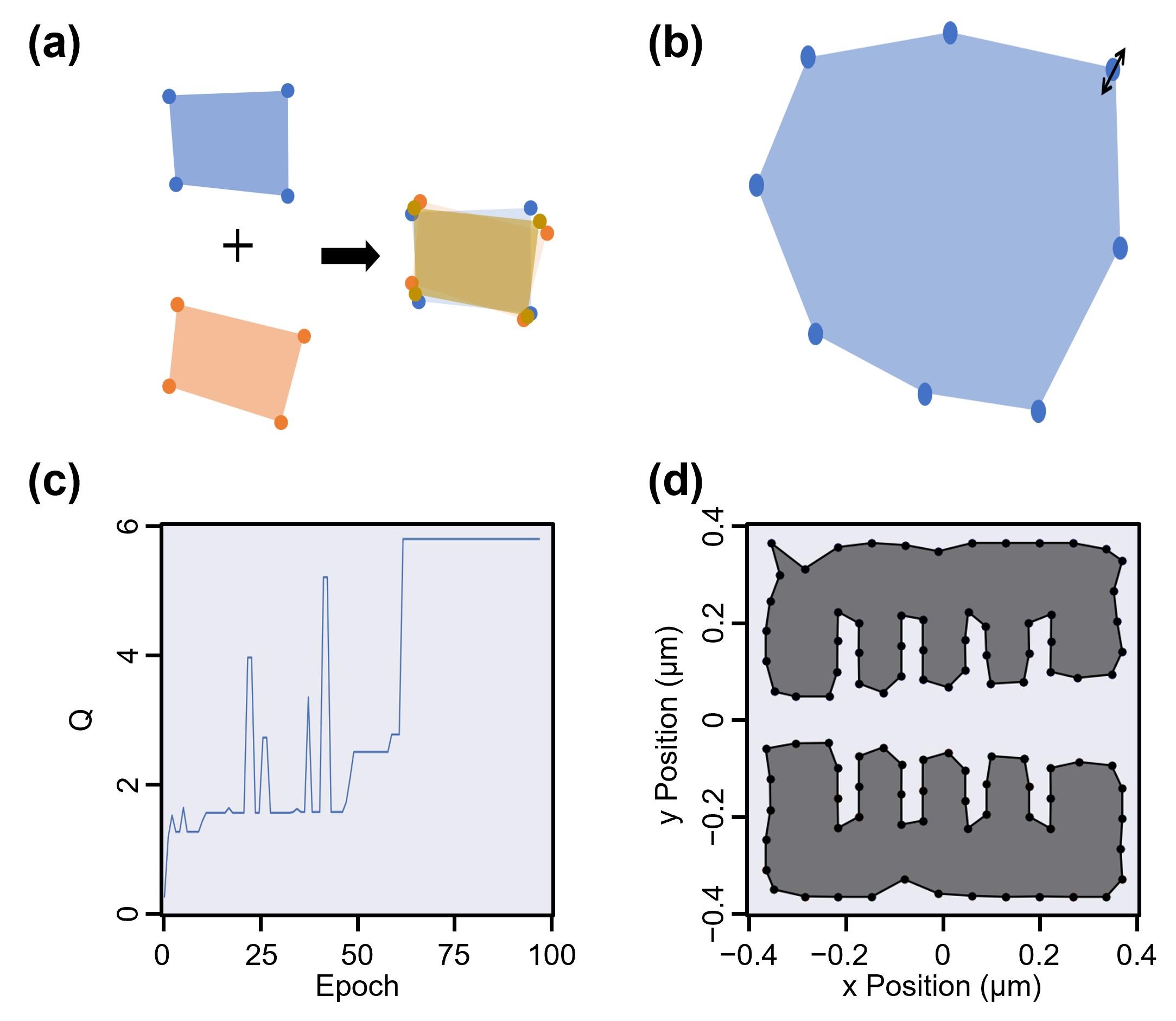

to evolve magnet shapes. This approach evolves a population of candidate micromagnet shapes, represented as

sophisticated 'MultiPolygonChrom' objects, over many generations.

The core of the algorithm is a custom fitness function that evaluates each candidate by first calling the

MuMax3 micromagnetic simulator via a C++ backend to compute the stray magnetic field.

It then calculates local field gradients using a 3x3 stencil method to determine the qubit quality factor

($Q = T_2^* \times \delta B_{driv}$) at specific quantum dot locations.

A sophisticated penalty term was also introduced to enforce field uniformity across multiple dots,

ensuring individual qubit addressability. The evolution is driven by custom implementations of

tournament selection, geometric crossover via vertex blending,

and mutation via random vertex displacement.

Crucially, to ensure the final designs are robust against real-world manufacturing imperfections,

the framework includes an optional evaluation mode that simulates fabrication blur by applying Gaussian

offsets to the polygons and averaging the fitness over these perturbed samples.

The result is a fully automated and robust pipeline that successfully designs non-intuitive magnet geometries

for improved qubit performance.